In modern industrial projects, refractory concrete dryout is an important step to ensure the durability and heat resistance of the boiler lining. At Heatco, we provide refractory dryout services with specialized burner systems, meeting customers’ strict requirements for quality and safety.

Heatco’s Refractory Concrete Dryout Process

Refractory materials are usually installed by casting, spraying or hammering on site. To achieve optimal heat resistance properties, the lining must be carefully dried to remove residual water from the casting process and help form strong ceramic bonds inside.

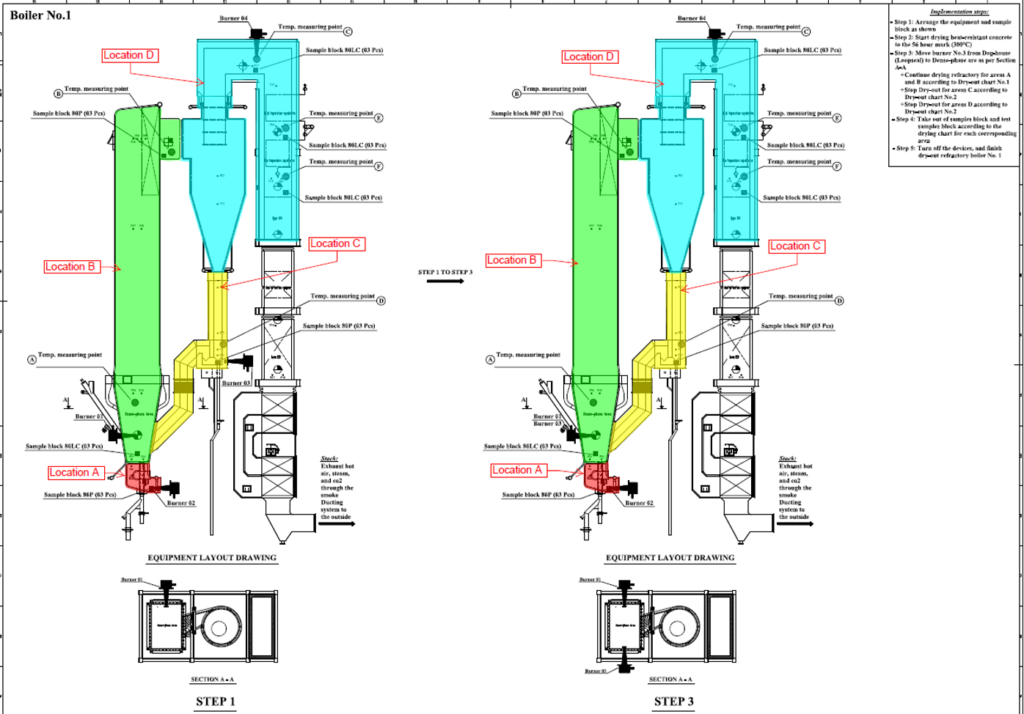

Heatco applies a special heat cycle from ambient temperature to the highest temperature, following the exact heat chart from the manufacturer. This helps to ensure temperature uniformity across the entire lining, increase the pressure inside the vessel and maintain the necessary atmospheric changes to remove all moisture.

Specialized Burner for Refractory Drying Heat

The difference of Heatco’s dry out service is the exclusive burner system, specially designed to perform the refractory dry-out process with maximum productivity and efficiency. Heatco burners are capable of reducing the temperature to very low levels while maintaining a large amount of combustion air, helping to increase the pressure in the tank and ensuring that no local overheating occurs.

- Safe and efficient dryout: Heatco burners can operate at a reduction ratio of 25:1 or lower, keeping the flame temperature at a safe level and preventing the risk of local damage to the liner.

- Guaranteed liner life: Proper dryout helps the refractory liner achieve the desired properties and prolongs its service life.

Why Choose Heatco for Refractory Dryout Service?

Heatco not only provides services but also brings peace of mind to customers through a professional and standardized dryout process. Investing in a high-quality refractory lining requires a standardized dryout process to ensure optimal heat resistance and long life for boilers and other industrial equipment.

- Professional and safe: Heatco has a team of experienced experts in the field of refractory dryout, ensuring that the process complies with strict safety standards.

- Cost savings: With a standardized dryout service, customers can save on maintenance and lining replacement costs in the long run.

Contact Heatco for detailed advice on boiler refractory concrete drying services, helping to ensure maximum durability and safety for your equipment. With Heatco’s refractory concrete drying service, you can be completely assured of quality and safety, while extending the life of industrial equipment.